How It’s Made

Did you know?

It would take 15,246,000 lbs of sunflower seeds to fill an olympic swimming pool with oil.

The Process

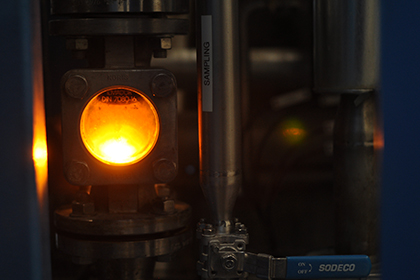

Crushing

Colorado Mills has a personal interest in the well-being of our consumers. We are a no-solvent extraction facility that only uses pressure to extract the oil from the sunflower seeds. Although our facility does not produce as high of a yield as other facilities that utilize petroleum based hexane solvents to extract oil from their seeds, we feel it is a safer, more beneficial process for our consumers.

Refining

The refining of our oil process is carefully monitored to ensure each batch of oil is finished to the highest quality. Our refining process does not use synthetic chemicals and does not winterize the oil. The winterization process can strip the oil of nutrients and vitamin E. Our end product has a simple ingredient list – 100% natural sunflower oil. The natural occurring oleic acid in sunflower oil allows our oil to perform better than chemical filled oils in restaurants and your kitchen.

Packaging

Colorado Mills has a wide range of volumes that our sunflower oil is packaged in. From each bottle to every railroad car Colorado Mills takes pride in packaging our sunflower oil.

- 750 ml Bottles

- 35 lbs JIBs

- 420 lbs Drums

- 2,000 lbs Totes

- 45,000 Semi Tankers

- 25,000 gal Railroad Cars